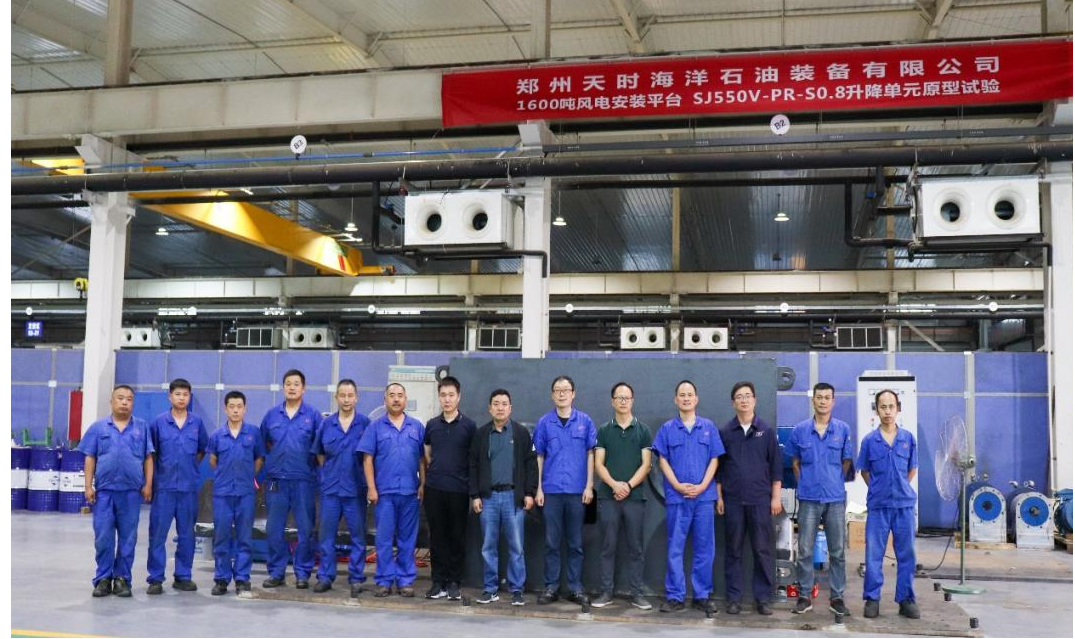

Through September 21st to 22nd, the prototype test of SJ550V-PR-S0.8 jacking unit was successfully completed in the workshop. This jacking unit was independently designed and developed by Zhengzhou Tianshi Offshore Oil Equipment Co., Ltd(Zhengzhou Tianshi), a wholly-owned subsidiary of CMIC. The loading and nondestructive testing of the jacking unit was inspected by the surveyor of China Classification Society (CCS) on site. With 1.1 times of the maximum static support load as test load, the final inspection was successfully passed and the product design and quality were fully affirmed by the surveyor.

SJ550V-PR-S0.8 jacking unit is the new type of frequency-driven gear-rack jacking system, which adopts the cutting edge design concept and processing technology in gear industry and has many advantages such as long life expectancy, optimized structure, convenient installation, large capacity, reliable and easy for maintenance. This type of jacking unit is suitable for the mainstream large scale offshore self-elevating wind turbine installation vessels, and is the key installation equipment of the next generation of large wind turbine for deep and distant offshore.

|

|

SJ550V-PR-S0.8 jacking unit has a rated lifting capacity of 250T, a pre-ballast lifting capacity of 375T, a static holding capacity of 680T, a storm holding capacity of 680T, a rated lifting speed of 0.8m/min, a pile leg lifting speed of 1m/min, a design fatigue life of 3000h (≥2500 times), a 55kW motor configuration, and sufficient power reserve capacity. Meanwhile, it is equipped with a self-developed torque sensor to monitor the load distribution at the climbing gear end in real time, which provides important safety guarantee for wind turbine installation.

SJ550V-PR-S0.8 jacking unit is the latest product which integrates 20+ years of research experience in marine transmission equipment engineering after series products such as jacking system for JACKUP, LIFTBOAT and marine hydraulic pin platform etc. It is completely suitable for the frequent shifting operation of marine wind turbine installation vessels and a better choice for offshore wind power platform construction projects.

Offshore wind power is the core to the future development of the wind power sector. The advantages include stable wind, high utilization rate of turbine, no land occupied and no noise. However, high waves at sea has created problems for wind turbine installation, leading to low operation efficiency is low and poor stability and safety. In particular, global offshore wind turbine unit capacity continues to grow and offshore wind farm construction is gradually moving to the deep sea, so large offshore wind power installation vessel function optimization has been on the agenda, in order to bring optimal and safer operations, improve operation efficiency and break the boundaries of the weather window and subsea conditions for offshore installation.

In this backdrop, the market demand for offshore wind power installation vessels has increased, and the prospect of a new generation of deep-sea large wind turbine construction and installation vessels is promising. With the global promotion of carbon emission reduction policy, a large number of offshore wind power projects at home and abroad have entered the construction stage, and the offshore wind power business of CMIC has market development potential.